Sieving Method

Wet sieving method is considered when the particle that is going to be used is already exists as wet or suspension.

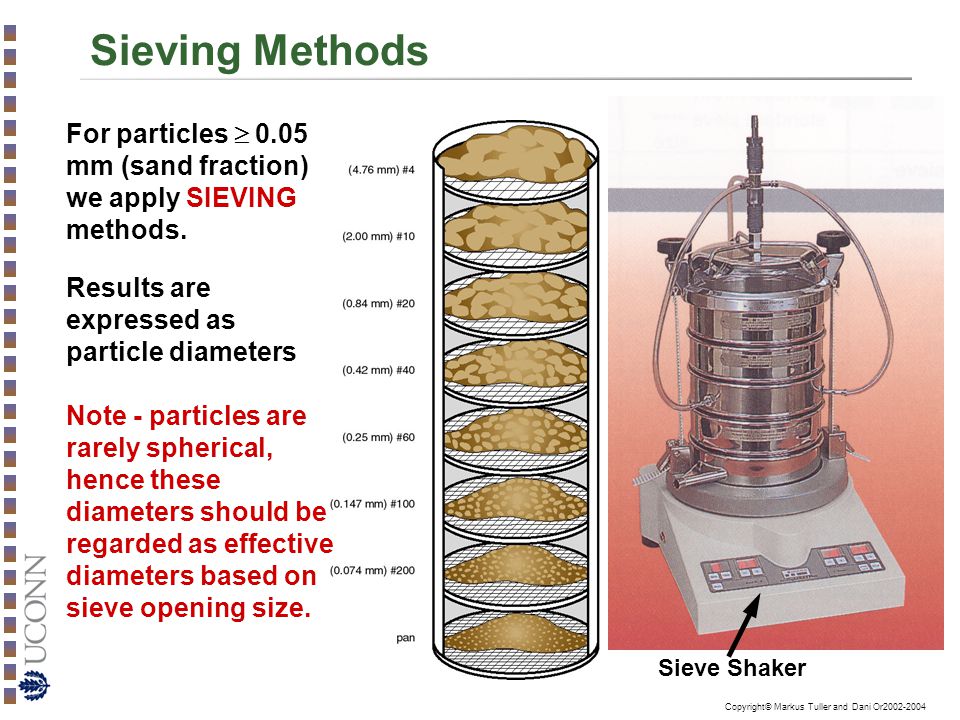

Sieving method. The basic principle involved in this method is size separation using standard sieves or screens 1 size separation is a unit operation that involves the separation of various sizes of particles into two or more portions by means of screening surfaces 2. Sieving is done by using a device to separate different sizes of materials. The sieves should be immersed in the ultrasonic cleaning bath and then dried thoroughly before reuse. Some experiments might require wet wash sieving.

Dry sieving method is considered mostly and here the testing particles specimen are in dry state. Ultrasonic cleaning should be conducted on a regular basis after testing. Sieving is a simple method that is used for determining the psd of a powder. Iso 3310 1 1982 test sieves technical requirements and testing part 1.

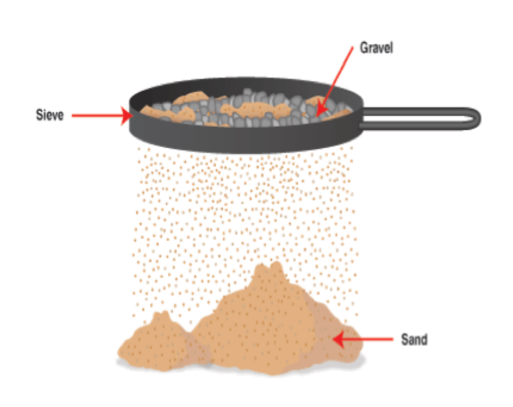

Sieving is a method of using a sieve to distinguish small particles from bigger particles. During this process the particles are compared with the apertures of every single sieve. Impurities such as husks and stones are extracted from wheat at flour mill. Sieve method or the method of sieves can mean.

Test sieves of metal wire cloth 95 99. Sieving methods of sieve analysis during sieving the sample is subjected to vertical movement vibratory sieving or horizontal motion horizontal sieving. Methods using test sieves of woven wire cloth and perforated metal plate 90 93. It is often the preferred method of choice for formulators since it is a straightforward analysis that can be done during the formulation development process eg after mixing or granulation of a formulation.

It is used in flour mills or building sites. With tap sieve shakers both movements are superimposed. A sieve analysis can be performed on any type of non organic or organic granular. Test sieving part 1.

Ultrasonic cleaning is the best method to remove particles trapped in the mesh. They remove pebbles and stones from sand by sieving. The vertical movement sieving method is also known as throw action sieving and vibratory sieving methods. The size distribution is often of critical importance to the way the material performs in use.

For this evaluation sieving method is used. Iso 2591 1973 test sieving 95 99.

.jpg)

.jpg)